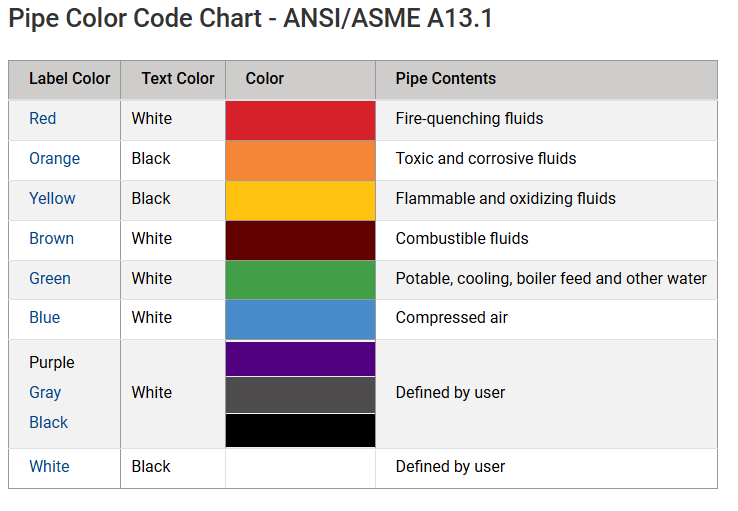

Pipe marking standards are not specifically outlined or defined by OSHA, but standard number 1910.261(a)(3)(ii) notes the ASME's (ANSI) standard A13.1 as the recommended scheme for identification of pipe systems.

The ASME Standard for Pipe Identification is a widely used guideline in determining pipe identification requirements. The ASME A13.1-2020 notes indicate that, "A13.1 is intended to establish a common system to assist in identification of hazardous materials conveyed in piping systems and the materials’ hazards when released in the environment." It goes on to identify that this scheme provides pipe system identification recommendations for industrial workplaces, power plants, commercial and institutional installations and buildings used for public assembly.

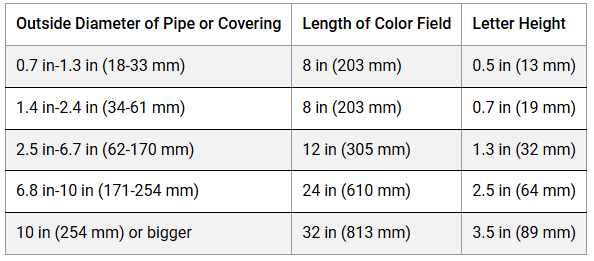

The ANSI standard A13.1 on pipe marker visibility and size requirements was updated in 2020, resulting in slight changes from the previous (2015) requirements. When considering the size and placement of lettering on your pipe marker, consider that, “Attention should be given to the visibility of the pipe markings. Where pipelines are located above or below normal line of vision, the lettering should be placed below or above the horizontal centerline of the pipe.”

In cases where it is difficult to label a pipe or covering due to size, we advise using durable and long-lasting energy source or valve tags in place of pipe labels or markers.

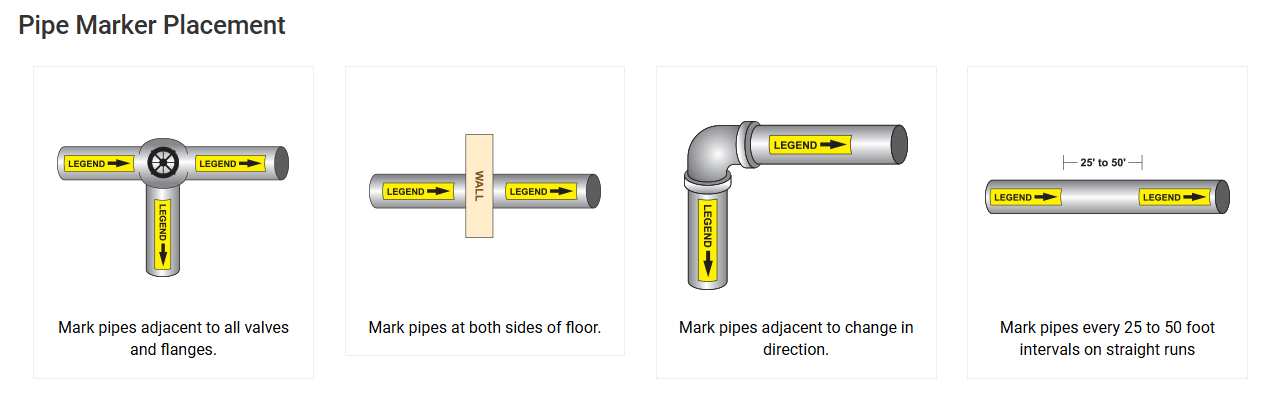

Now that we know what our pipe labels need to look like and how big they need to be, we need to understand where they go.