|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

Product name: Product name: Multi Loose Tube Optic Fiber Cables |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keywords: Addison Multi Loose Tube Optic Fiber Cables Keywords: Addison Multi Loose Tube Optic Fiber Cables |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

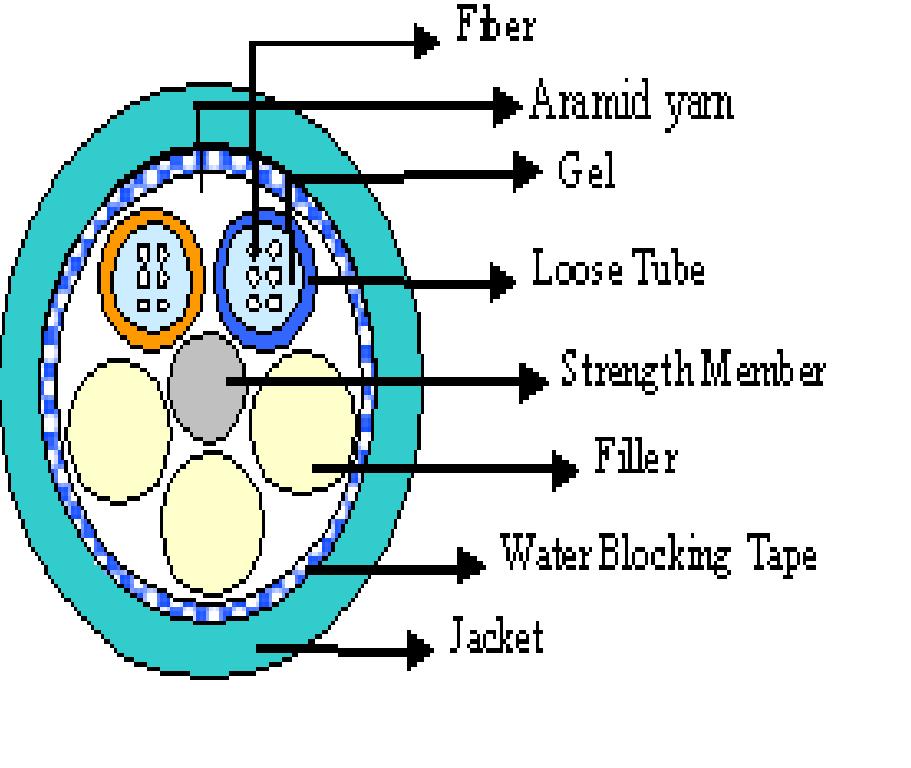

Product Picture Product Picture |

|

|

|

|

| |

|

|

| |

|

|

|

|

|

|

Product Introduction Product Introduction |

|

|

|

|

|

|

|

|

Multi Loose Tube Optic Fiber Cables |

|

|

|

|

|

|

|

|

|

|

|

|

Applications: |

Long Distance Outside Telephone/CATV/Data Communications |

|

|

|

|

|

Installations: |

Installed in Duct, Self Supporting ( Figure 8 Self Supporting or ADSS All Dielectric Self Supporting ), Direct Burial ( With Armouring ) |

|

|

Construciton: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The cable consists of 5 to 36 elements stranded in up to 3 layers around a central strength member and bound in a jacket .

The elements are usually fiber-containing tubes,however fillers are also used ,when needed,to preserve cable geometry .The cable can be ordered with a central member either made of a dielectric FRP,or made of solid or stranded steel coated with polyethylene.

Two to twelve color-coded fibers are loosely laid in each tube that is filled with a water-blocking gel.Standard tube diameters are 2.1mm for up to 6 fibers per tube and 2.5mm for 8 to 12 fibers per tube.However,other tube diameters and cable configurations are available.

The total number of fibers ranges from 4 to 432.A wide range of jacket options is available:polyethylene,halogen-free flame-retardant material,corrugated anti-rodent steel armoring,fiberglass armorning ,aramid yarn ,and more.A ripcord is located under esch jacket layer to facilitate jacket removal. |

|

Physical Characteristics: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maxiumum Transmission Distance: 6km ( Single Mode ) 0.3km ( Multimode ) |

|

|

|

|

|

Max Pulling Load: |

Short Term Installation: 1500 ——2700N |

|

|

|

|

|

|

|

|

|

|

|

|

|

Long Term Installation:

900 ——1500N |

|

|

|

|

|

Minimum Bending Radius: |

Short Term Installation: 20 x OD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long Term Installation: 10 x OD ( Non armoured ); 20 x OD ( Armoured ) |

|

|

|

|

Twist ( Torsion Length ) : 125 x OD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working Temperature: -40°C ——+70°C ( PE Sheath ) |

|

|

|

|

|

|

|

|

|

|

Storage Temperature: -50°C——+70°C ( PE Sheath ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Highlights : |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Central Member , which is usually either made of a dielectric FRP,or made of solid or stranded steel coated with polyethylene.

All the fiber contraining

are placed at the centre of the cables. All the fibre containing tubes are placed in concentric layers around the central member and through the control of the twist length, the fibre cable can achieve better pulling load and operating temperature.

Tube Materials are water resistant and can sustain high tension. Being filled with special water blocking gel, the tube can provide water protection for the fibres inside the tube.

Cables Interstices are also filled with water blocking gel to preserve cable geometry. |

|

Ordering Information : |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AD-LDA-B -C×D -E -F -G -H- I |

|

|

|

|

|

|

|

|

|

A- Loose Tube Diameter : |

B-2.1mm;C-2.5mm;D-2.8mm;E-3.0mm;F-3.2mm. |

|

|

|

|

|

|

B- Fiber Type: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-Fibers and copper conductors in cable;1-Two or more fiber types in a cable,Specify fibers by a remark;5-50/125 multi-mode;6-62.5/125 multi-mode;8-NZDS SM fiber per G.655;9-Standard SM fiber per G.652. |

|

|

|

|

|

C- NO.of Tubes: 1-36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D — No of Fibers per Tubes : 2 - 12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E— Central Member :M-Solid steel;B-Stranded steel;D-Dielectric(FRP). |

|

|

|

|

|

|

F— - - Jacket |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Options :P-Polyethylene;V-PVC;H-Halogen-free,Flame-Retardant;R-Corrugated Steel Armoring;J-Dielectric Armoring;K-Aramid Yarns;M-Combined Fiberglass;A-Aluminum Moisture Barrier;T-Anti-Termite Protection;W-Steel Wire Armoring;Z-Glass Yarn Strength Members |

|

|

|

|

|

- G — Cable Core Water-Blocking Options:X-No water-blocking;G-Water-blocking gel;D-Dry water-blocking;M-Mixed Water-Blocking-gel and dry. |

|

|

H — Jacket Water-blocking Options (for cables with more than one jacket):X-No water-blocking;G-Water-blocking gel;D-Dry water-blocking. |

|

|

I — General Options:SS-Figure-8 Self-Supporting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] [2] [3] [4] |

|

|

|

|

|

|